-

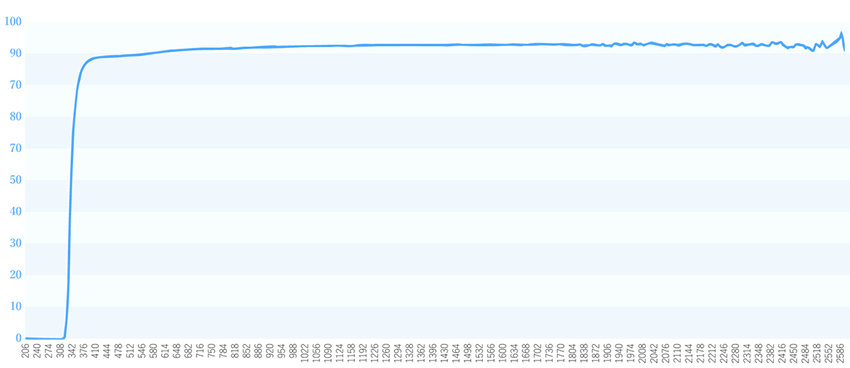

Transmittance(τ=1mm)

λ80

λ80

360nm -

Overview of features

Item NANOCERAM™ Chemical strengthened glass

(Competitor's product)Sapphire Glass COST ○ ◎ × Impact resistance ◎ ○ × Hardness ○ × ◎ Bending strength ◎ × ◎ Thermal shock ○ × ◎

Made in Japan

OHARA is a company founded in Japan with a history of 80 years.

The wide range of glass products provided by OHARA are highly regarded around the world.

As an optical trading company, Tamapack highly recommend OHARA's NANOCERAM™, in order to respond the high-level demands of our customers.

NANOCERAM™ Introduction Not Glass. Not Ceramics. It's a New Glass ceramics.

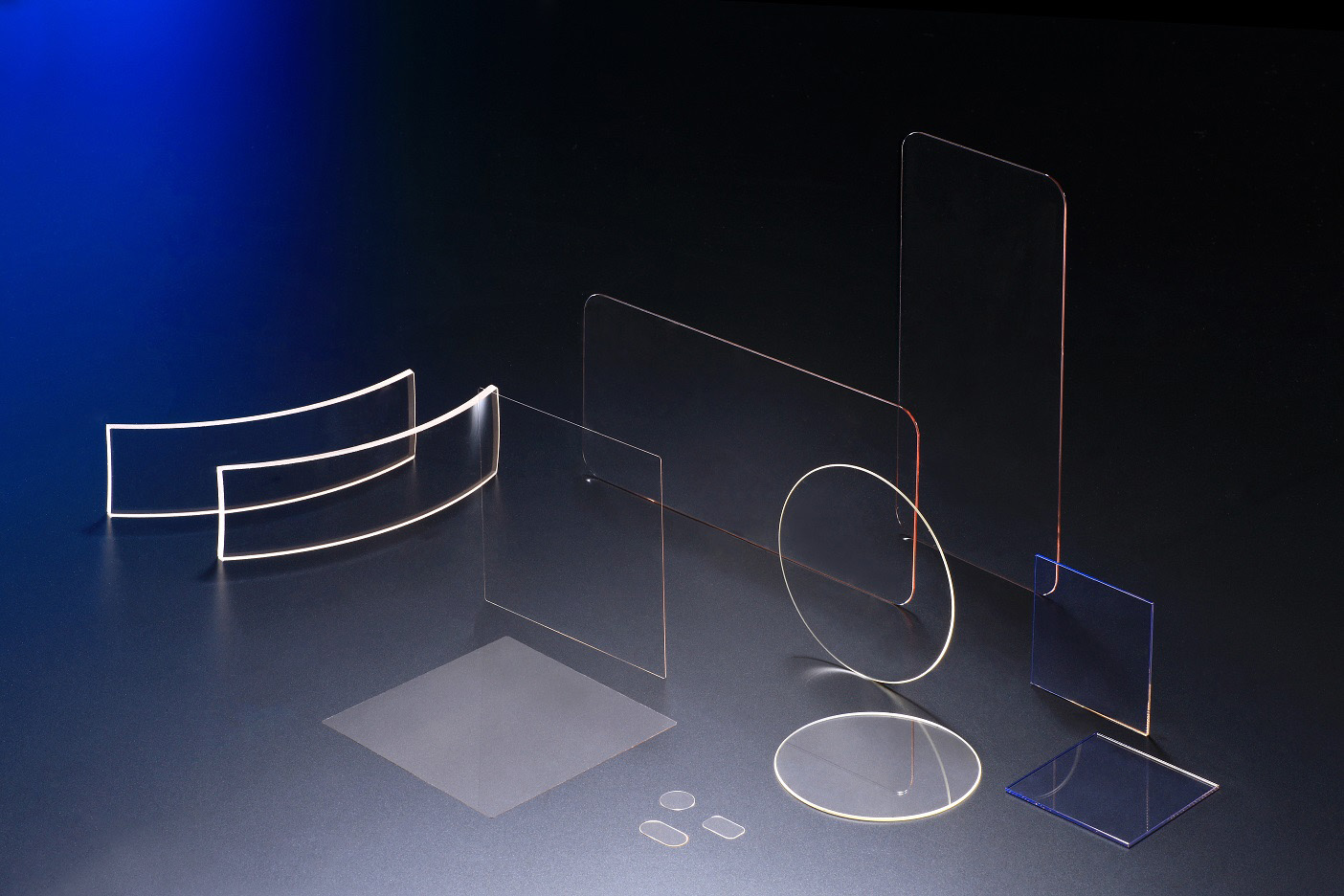

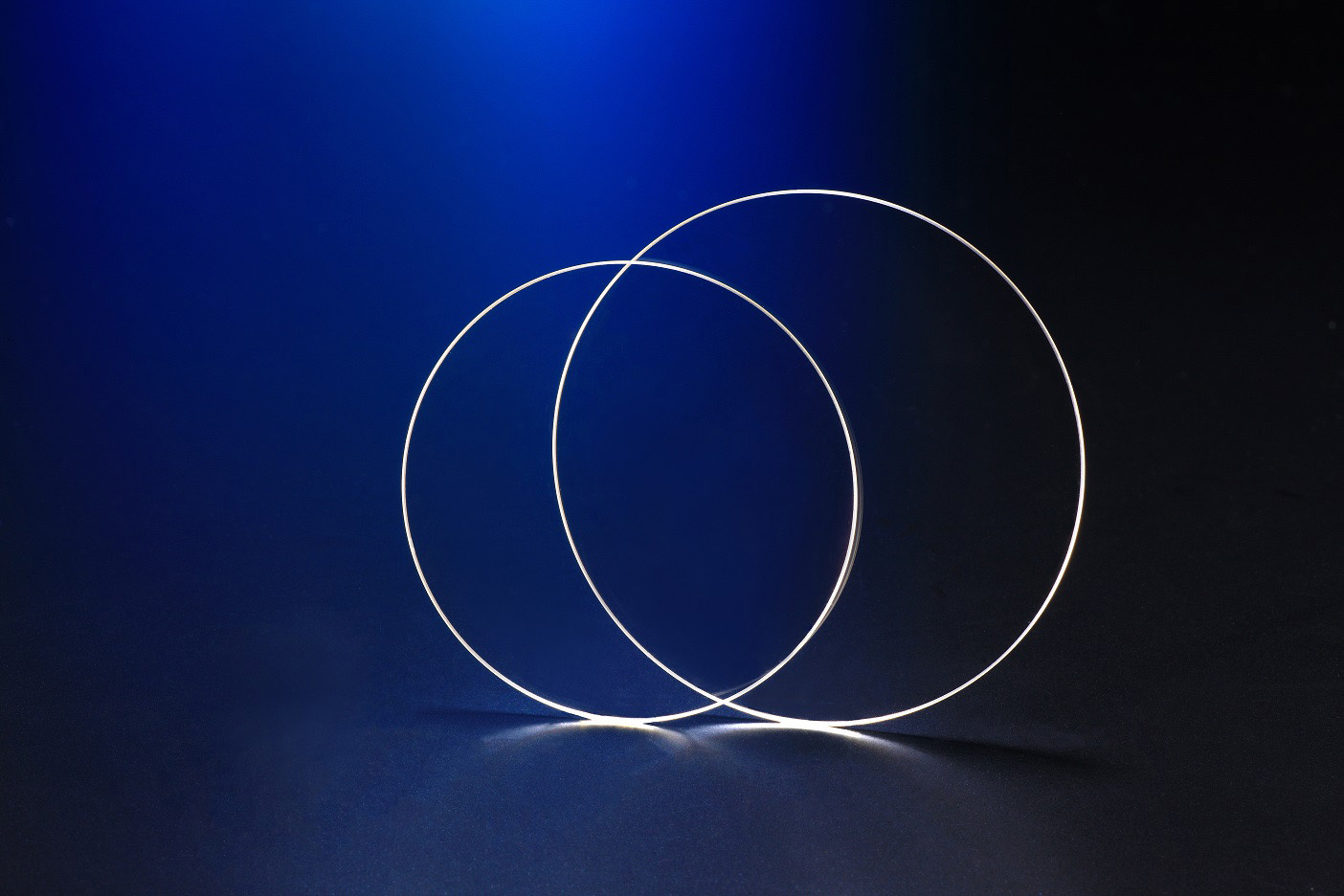

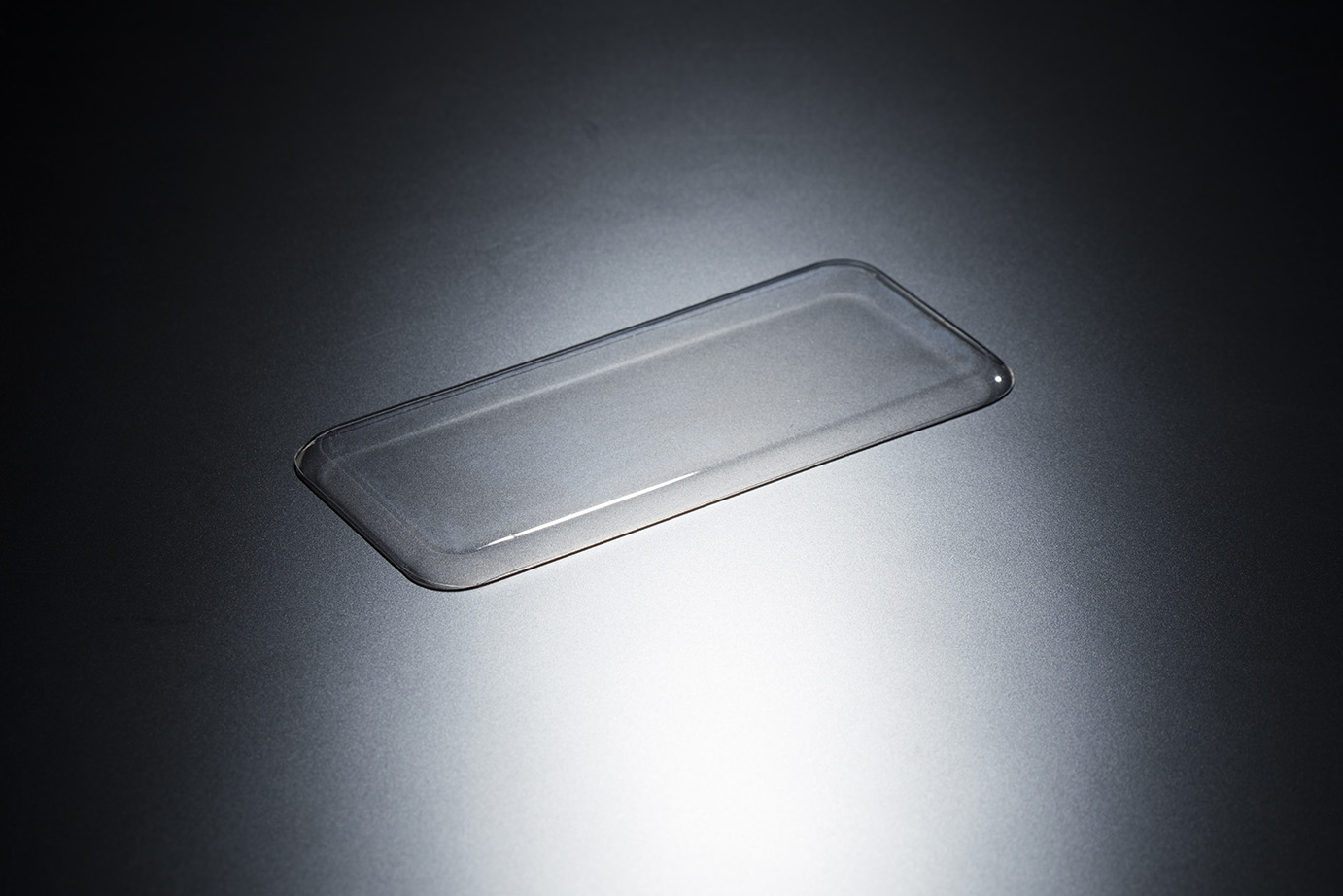

NANOCERAM™ is a new glass ceramic material featuring extremely high strength, high transmittance, and excellent machinability. It is a further evolution of OHARA’ s crystallized glass, which has been highly regarded in space, astronomy and a wide variety of other fields.

With NANOCERAM™ we propose new value for applications in optical instruments and cover glass for mobile devices, which require strength that cannot be achieved with sapphire crystal glass or chemically strengthened glass.

- 01|High Hardness

- 02|High Impact Resistance

- 03|High Transmitance

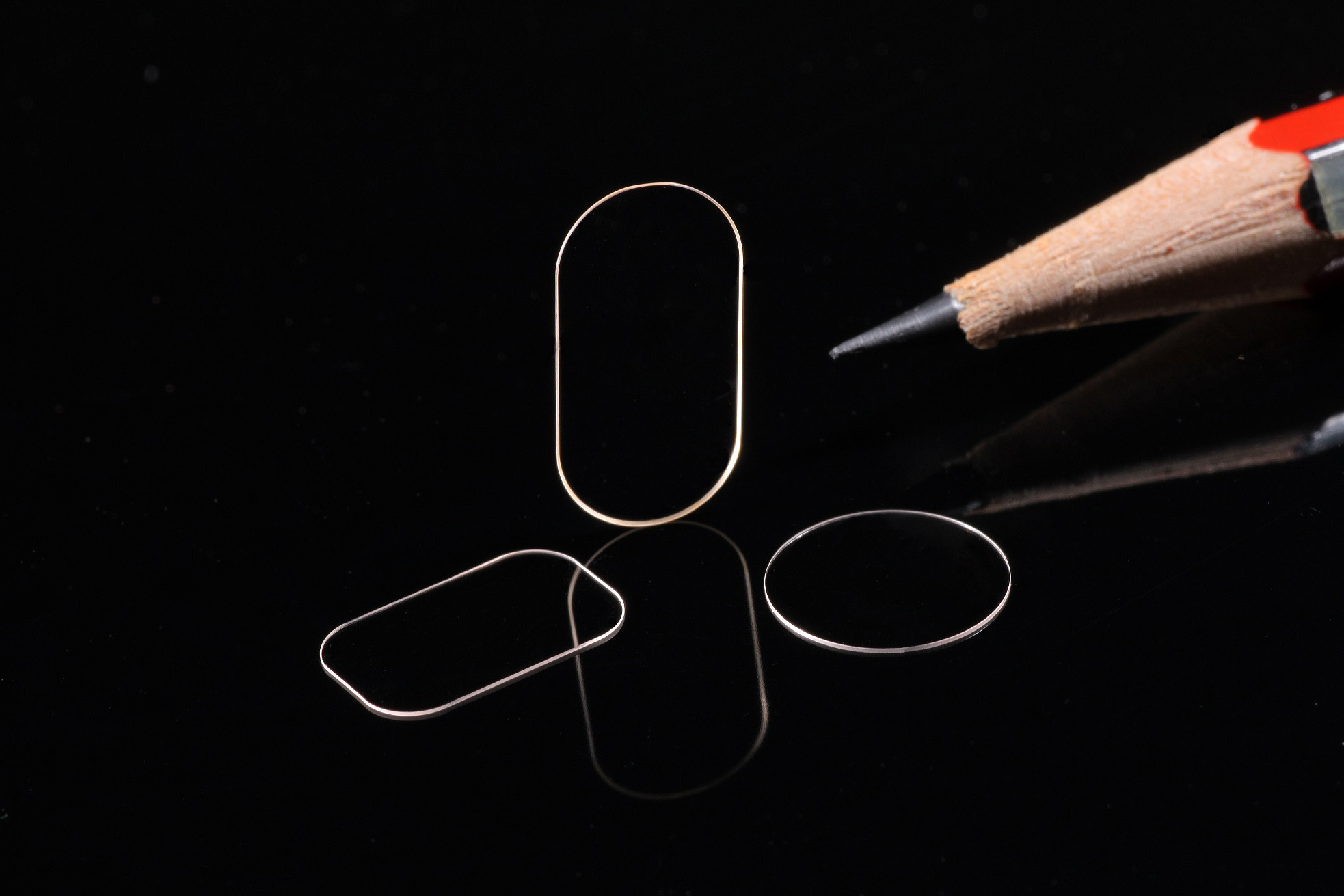

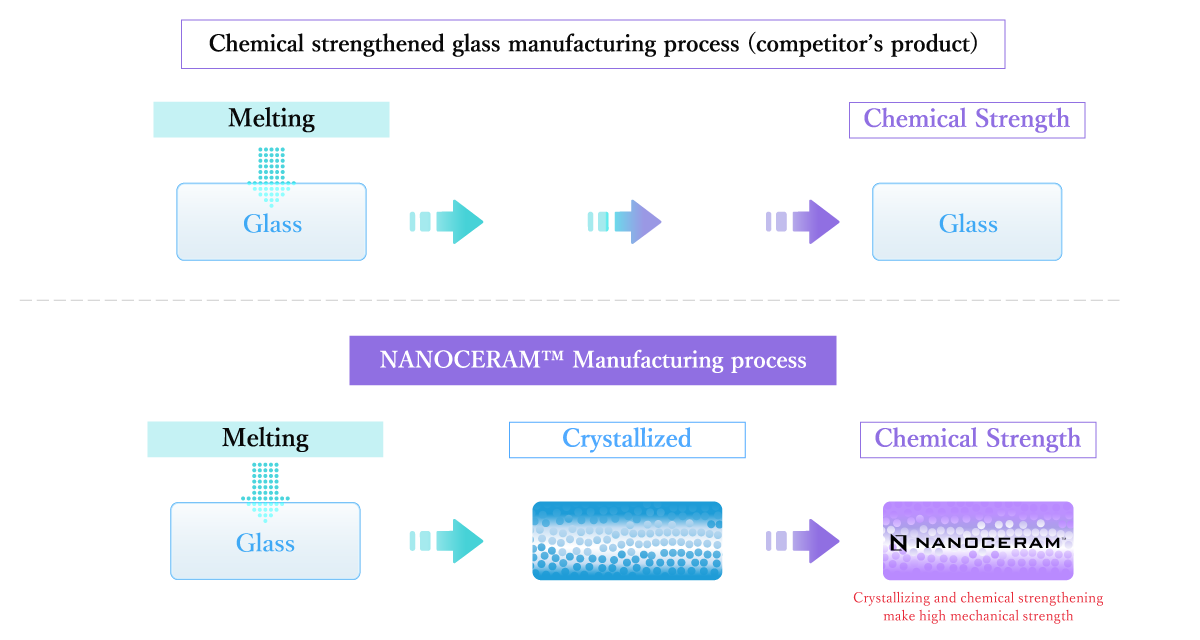

NANOCERAM™ is a glass ceramic made by applying heat treatment to glass materials and extracting extremely small crystals.

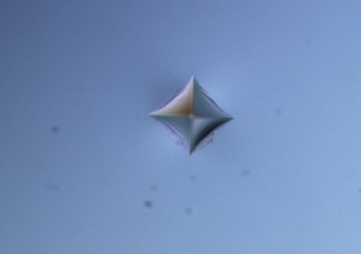

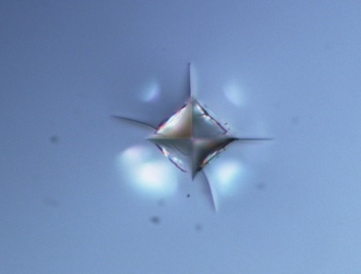

These crystals, invisible to the naked eye, stop scratches and defects frim spreading, enabling high strength that is not possible with conventional glass.

Advantages of NANOCERAM™

Compared with general borosilicate glass, NANOCERAM™ has 30% higher hardness and showed more than 10 times higher impact resistance in steel ball drop impact tests. In addition, it has 20% higher hardness than highly-strong chemically strengthened glass, and showed more than 3 times higher impact resistance in steel ball drop impact tests.

Also, as NANOCERAM™ has better fracture toughness than sapphire crystal glass and features strong resistance to cracking, scratches will not lead to cracks that cause breakage.

Vickers Hardness test result

*Tests related to scratch resistance

| MATERIAL | Hardness |

|---|---|

| NANOCERAM™ | 710 |

| Chemical strangthened Glass (competitor's product) |

650 |

Check for crack growth

→Restraining

crack growth

*competitor's product

→Crack growth

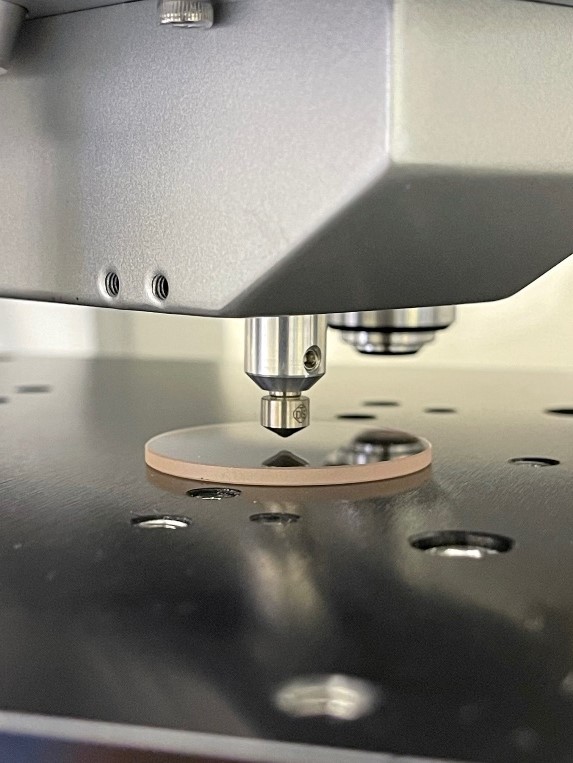

Differences in manufacturing process

Test Result

-

Impact resistance test VS. Steel Ball (1,500g) MATERIAL

(t=2mm)Height

20cmHeight

60cmNANOCERAM™ ○

Not Broken○

Not BrokenChemical strengthned Glass (competitor's product) ×

BrokenSapphire Glass ×

Broken*Reference Test

-

4-point bending test MATERIAL

(@0.6mmt)Bending strength (MPa) NANOCERAM™ 1,180 Chemical strengthned Glass (competitor's product) 590 *Reference Test

Characteristic

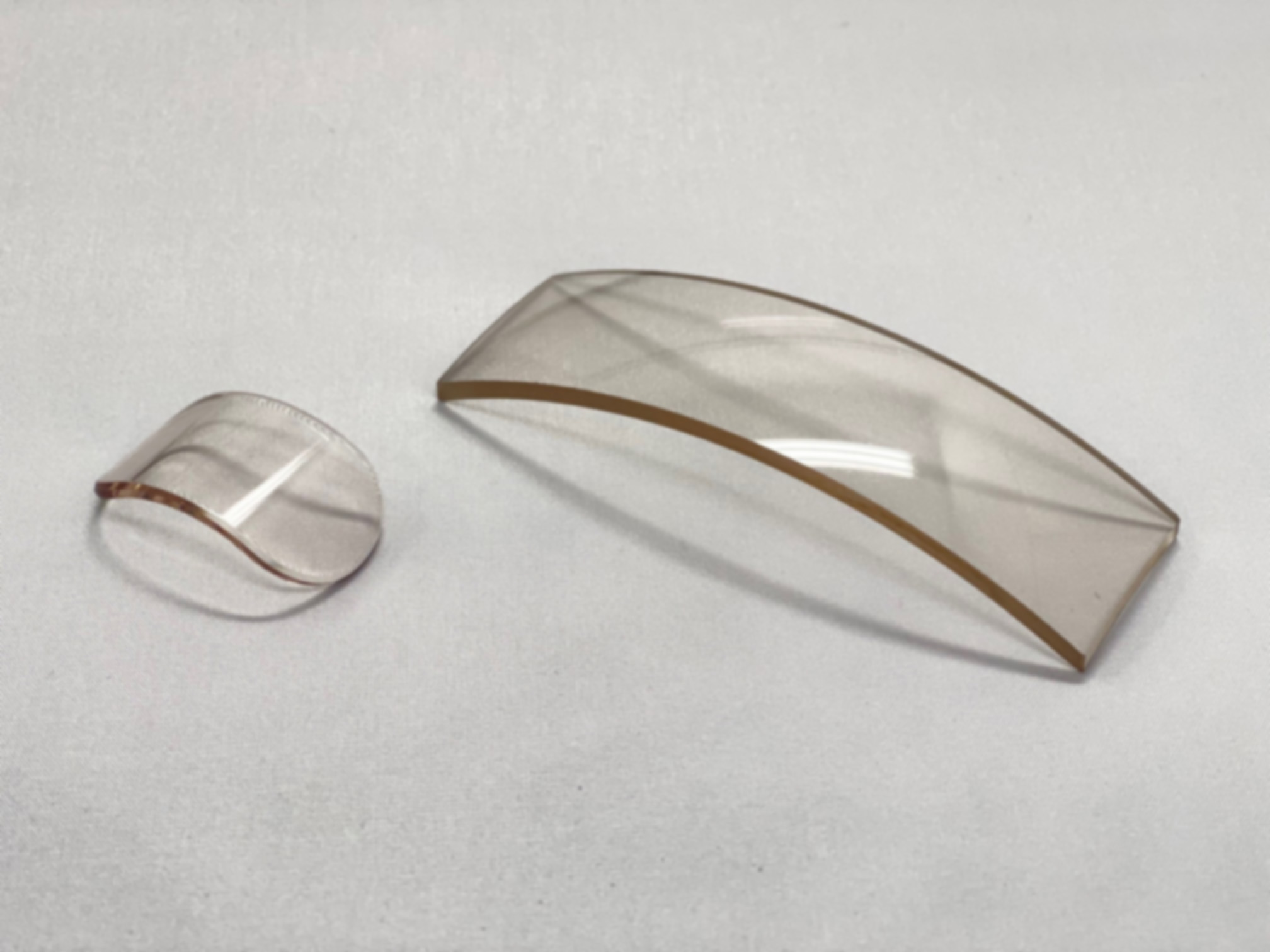

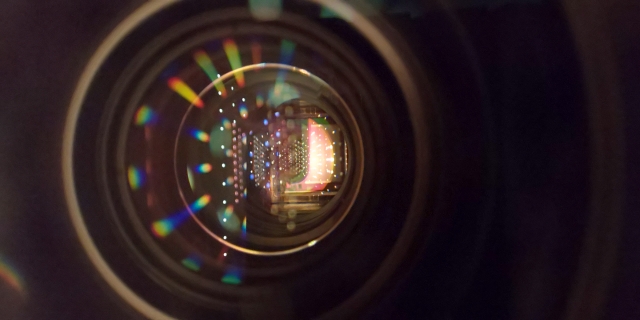

Conventional glass ceramics had large crystal grains, making it difficult to transmit light, so they were never used for optical applications. However, with the realization of high transparency using OHARA's nanocrystallization technology (particle diameter of about 6 mm), which has a strong track record in the space and astronomy fields, NANOCERA™ is mounted on high-end lens protectors for single-lens reflex interchangeable lenses of domestic manufacturers who demand strict optical performance and precise quality, and has received strong praise.

| Item | NANOCERAM™ | Chemical strengthened glass (Excerpt from competitor's website) |

|---|---|---|

| specific gravity | 2.54 | 2.40 |

| Expansion Coefficients α×10-7/℃(-30~+70℃) | 74 | - |

| Expansion Coefficients α×10-7/℃(100~300℃) | 91 | 72.5 (0-300℃) |

| Yield Point (At) | 740 | - |

| Transformation Temperature (Tg) ℃ | 653 | - |

| Young's Modulues (GPa) | 80.2 | 77 |

| Rigidity Modulus (GPa) | 32.7 | 31.4 |

| Poisson's Ratio δ | 0.225 | 0.22 |

| Thermal Conductivity λ W/(m・K) | 1.17 | - |

| Vickers Hardness (200gf) | 710 | 651 |

| Dielectric Constant (54MHz) | 8.2 | 6.82 |

| Dielectric Constant (272MHz) | 8.1 | 6.77 |

| Dielectric Constant (490MHz) | 8.1 | 6.74 |

| Dielectric Constant (912MHz) | 8.1 | 6.81 |

| Transmittance %T @550nm 0.6mmt | 90.2 | 90.5 |

| Refractive Index (nd) | 1.539 | 1.51 |

| Water Resistance (Powder Method) RW(P) | 1 | - |

| Acid Resistance (Powder Method) RA(P) | 1 | - |

| Weathering Resistance (Surface Method) W(S) | 1 | - |

| Acid Resistace SR (Surface Method) SR | 1.0 | - |

| Phosphate Resistance PR (Surface Method) PR | 1.0 | - |

For all uses You want to Protect

-

Shooting / Projection

-

Measuring equipment

-

Medical Related

-

Space /Astronomical Objects

-

Communication Related

-

Mobile Related

-

Semiconductor Related

-

Automotive Related

CONTACT

Please feel free to ask any questions you may have.